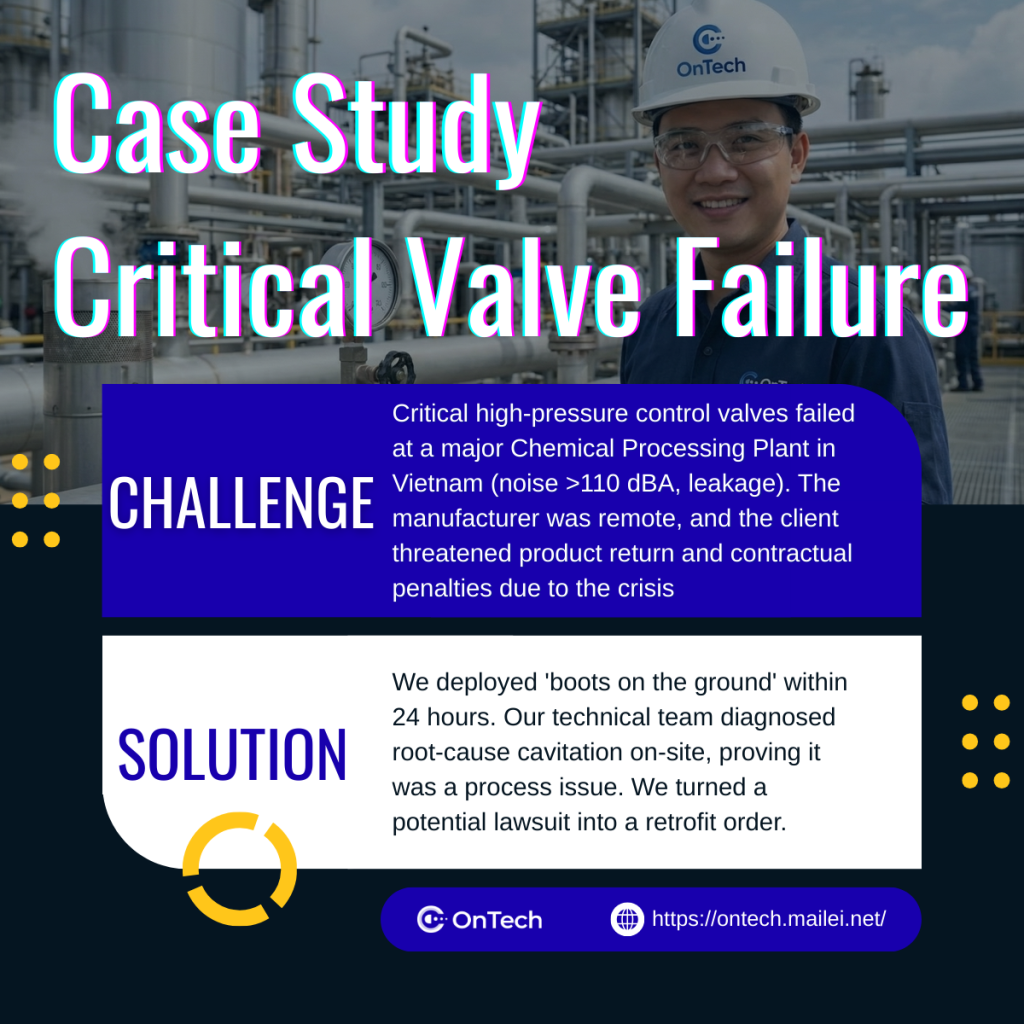

Equipment Type: Valves Industry: Chemical Processing Location: Dong Nai, Vietnam

At a Glance

The Client: A leading European Manufacturer of Control Valves.

The End-User: A major Chemical Processing Plant in Vietnam.

The Crisis: Critical valve failure (noise & leakage) immediately post-commissioning, leading to threats of product return and contractual penalties.

The Solution: OnTech deployed immediate on-site technical diagnostics, identifying root-cause cavitation and engineering a retrofit solution.

The Result: 100% Contract Retention + New Revenue generated from retrofit orders.

The Challenge: A "Perfect Storm" of Distance and Pressure

Following a successful tender, our client supplied high-pressure severe-service control valves for a critical Ammonia/Urea line at a large Chemical Processing Plant in Vietnam.

Three weeks after commissioning, the situation turned critical. The plant operators reported screaming noise levels exceeding 110 dBA, severe vibration, and gland packing leakage. The valves were failing to control the process, risking a plant shutdown.

The Logistics Gap: The manufacturer was based in Europe with no direct technical team in Vietnam. The Commercial Risk: Viewing this as a product defect, the end-user issued a formal notice threatening product return and significant contractual penalties. The manufacturer’s brand reputation in the region hung by a thread.

The OnTech Solution: In-Factory Technical Leadership

Unlike generalist sales agencies that simply forward complaints to HQ, OnTech Strategic Solutions acted as the manufacturer’s “dedicated, on-the-ground extension”. We leveraged our core pillar of “Specialized Technical Sales & Crisis Resolution” to intervene immediately.

- Rapid Deployment (The First 24 Hours) We mobilized a Senior Technical Lead to the site within 24 hours. This speed demonstrated commitment to the angry end-user and bought valuable time for the manufacturer.

- Root-Cause Diagnosis Using “in-factory” technical leadership, we conducted a forensic analysis of the valve performance on the factory floor.

- Observation: We correlated the DCS data with physical symptoms.

- Diagnosis: We identified that the actual process conditions differed from the original datasheet. The valves were operating at a low opening percentage with higher-than-expected inlet pressure. This caused severe cavitation—fluid flashing and imploding—which was destroying the trim and vibrating the packing loose.

- The Engineering Fix We translated the site data into a clear technical report for the manufacturer. We then presented a retrofit solution to the end-user: replacing the standard trim with a Multi-Stage Anti-Cavitation Trim and upgrading to live-loaded packing to handle the stress.

The Outcome

By bridging the gap between the European engineering team and the Vietnamese plant floor, OnTech achieved three decisive results:

- Commercial Rescue: We successfully proved the failure was due to process conditions, not manufacturing defects. This eliminated the risk of contractual penalties and returns.

- Revenue Generation: Instead of a warranty loss, the client secured a new Purchase Order for the engineered trim retrofits.

- Brand Protection: The end-user was impressed by the manufacturer’s ability (via OnTech) to provide local, high-level technical support. This turned a transactional vendor relationship into a trusted partnership.

Why It Matters

Global manufacturers often hesitate to enter complex markets like Vietnam due to the fear of remote support failures. This case proves that with the right partner, you can have “technical precision” and “on-demand agility” without the heavy overhead of a local subsidiary.

We don’t just sell; we resolve.

Ready to secure your industrial foothold in Vietnam?

Don’t let distance become your liability. Partner with OnTech Strategic Solutions to activate your industrial sales potential and ensure your technical reputation is protected on the ground.