Equipment Type: Drives & Motors Industry: Heavy Industry (Cement) Location: Ha Nam, Vietnam

At a Glance

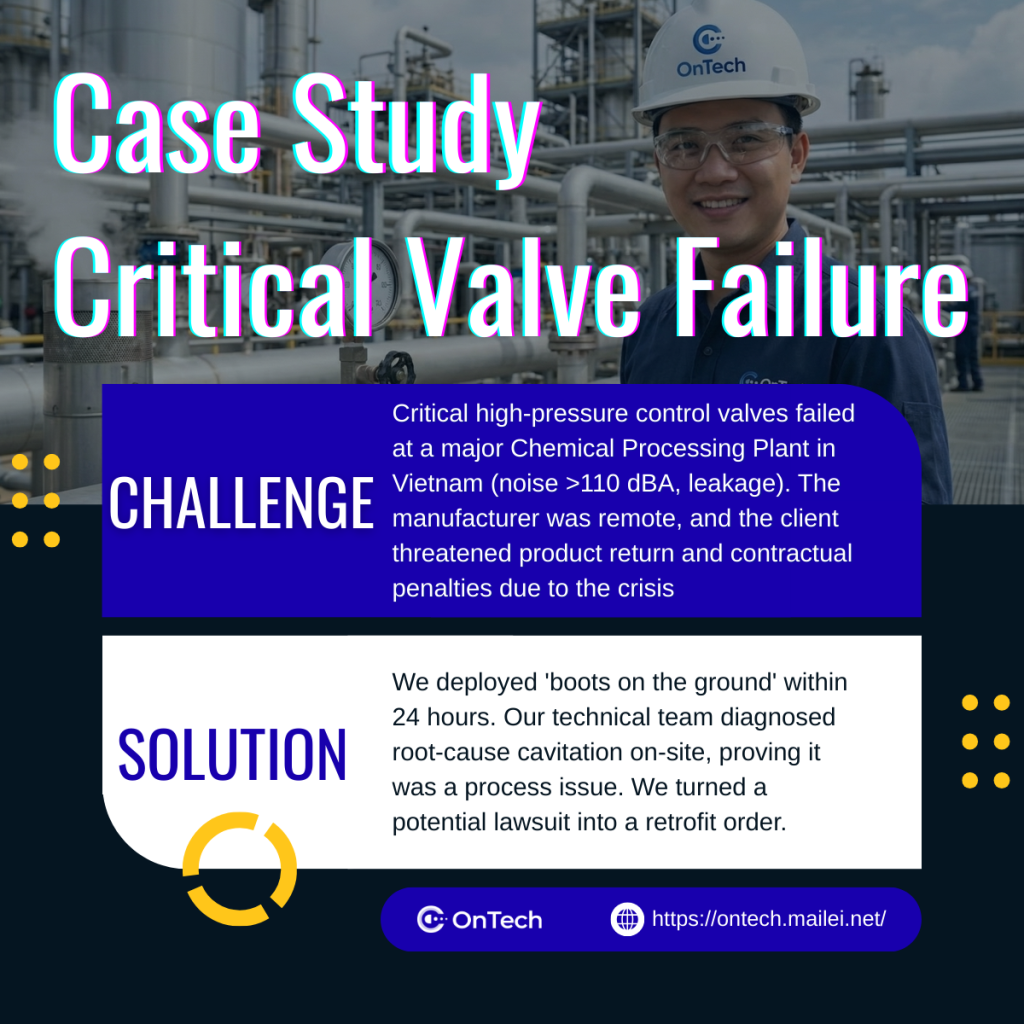

The Client: A leading European Manufacturer of Control Valves.

The End-User: A major Chemical Processing Plant in Vietnam.

The Crisis: Critical valve failure (noise & leakage) immediately post-commissioning, leading to threats of product return and contractual penalties.

The Solution: OnTech deployed immediate on-site technical diagnostics, identifying root-cause cavitation and engineering a retrofit solution.

The Result: 100% Contract Retention + New Revenue generated from retrofit orders.

The Challenge: A Commercial Standoff

“PowerDrive Systems” (anonymized) had successfully won a tender to retrofit high-efficiency Medium Voltage VFDs on a Kiln Induced Draft (ID) fan at a major cement plant.

However, just 12 weeks after commissioning, the situation turned toxic. The 2,500 kW motor bearings failed catastrophically. After a replacement, they failed again just 10 weeks later.

The “Blame Game”:

- The End-User: Blamed the new VFDs for “injecting bad power” and damaging the equipment. They withheld the final 20% retention payment and threatened to rip out the drives.

- The Motor OEM: Refused warranty, claiming their motors had operated flawlessly for 10 years prior to the VFD installation.

- The Client: Based in Europe, they lacked the local technical presence to defend their technology against these claims on-site.

The OnTech Solution: Forensic Technical Leadership

Acting as the client’s “dedicated, on-the-ground extension” , OnTech moved beyond standard sales support to provide “Specialized Technical Sales & Crisis Resolution”.

- The Investigation (In-Factory Diagnostics) Instead of relying on remote data logs (which showed no faults), OnTech deployed a Senior Electrical Specialist to the Ha Nam site. We looked beyond the VFD to analyze the electro-mechanical interaction of the entire drivetrain.

- The Root-Cause Discovery We performed a forensic inspection of the failed bearings.

- The Finding: We identified distinct “fluting” (washboard patterns) on the bearing races.

- The Diagnosis: This was a clear case of Electrical Discharge Machining (EDM). The rapid switching of the modern VFD was creating Common Mode Voltage on the shaft. Because the legacy motor lacked insulated bearings, this voltage was arcing through the bearings to ground.

- The Strategic Pivot We presented a technical report to the plant management proving the VFD was performing to IEC standards. The failure was a system integration issue due to the older motor’s lack of protection, not a defect in the drive.

- The Fix: We supervised the installation of Shaft Grounding Brushes to bleed the voltage and specified insulated bearings for the next overhaul.

The Outcome

By leveraging “technical precision” to identify the invisible root cause, OnTech resolved the deadlock:

- Financial Recovery: The End-User acknowledged the root cause. The 20% retention payment was released immediately.

- Commercial Defense: The warranty claim against the VFDs was officially dropped.

- Operational Stability: The motors have now run for over 18 months with zero failures.

- Trust: The client is now the preferred vendor for the plant’s upcoming grinding mill expansion.

Why It Matters

In complex industrial environments, sales often stall at the intersection of different technologies (Drive vs. Motor). Without “in-factory” technical leadership, manufacturers risk losing revenue to unfair technical claims.

OnTech bridges the gap between your innovative solutions and the complex reality of the factory floor.

Ready to protect your technical reputation in Vietnam?

Don’t let distance and technical ambiguity freeze your capital. Partner with OnTech Strategic Solutions to ensure your interests are defended on the ground.